PROJECT

Poly(lactide)-Based Functional Materials

●Polylactides (PLAs)

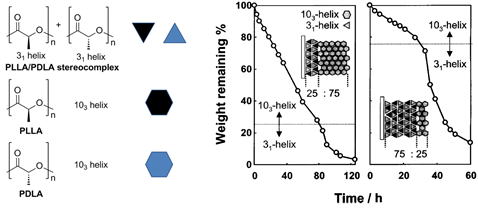

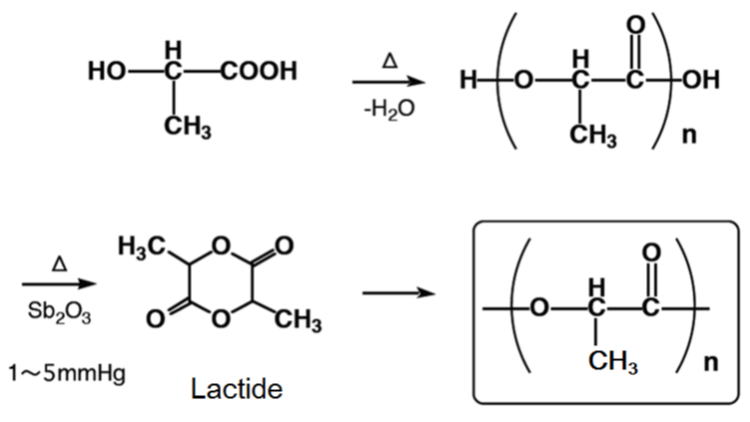

Polylactides (PLAs) are polymers from renewable resources. Since PLAs are biodegradable and biocompatible, they can be applied to environmentally compatible materials and biomaterials. There are poly(L-lactide) (PLLA), which derived from natural products, and its enantiomer poly(D-lactide) (PDLA). The mixture of PLLA and PDLA forms a stereocomplex through their van der Waals interactions, and the stereocomplex possesses different properties from the single PLLA or PDLA.

In our laboratory, the materials composed of PLLA and PDLA are fabricated and investigated by various approaches.

1. Hydrolysis Control

The alternative layer-by-layer assembly technique is applied to fabricate PLLA/PDLA stereocomplex thin films on a substrate. The alkali hydrolysis of the films are monitored to find that PLLA/PDLA stereocomplex is decomposed easier than single PLLA or PDLA crystals. This result indicates that the difference of crystal structures affected the hydrolysis behavior. We investigate the hydrolysis behavior and control of the PLA hydrolysis.

References

(1) Yuuya Arikawa, Takeshi Serizawa, Takashi Mukose, Yoshiharu Kimura, Mitsuru Akashi, “Controlled

Degradation of Porous Poly(lactide) Stereocomplex Films Prepared by the Selective Extraction of

Co-assembled Poly(vinyl alcohol)”, Polym. Bull., 58, 703-709 (2007).

(2) Takeshi Serizawa, Yuuya Arikawa, Ken-ichi Hamada, Hiroo Yamashita, Tomoko Fuijwara, Yoshiharu

Kimura, Mitsuru Akashi, “Alkaline Hydrolysis of Enantiomeric Poly(lactide)s Stereocomplex Deposited on

Solid Substrates”, Macromolecules, 36, 1762-1765 (2003).

2. Nanostructure and Morphology

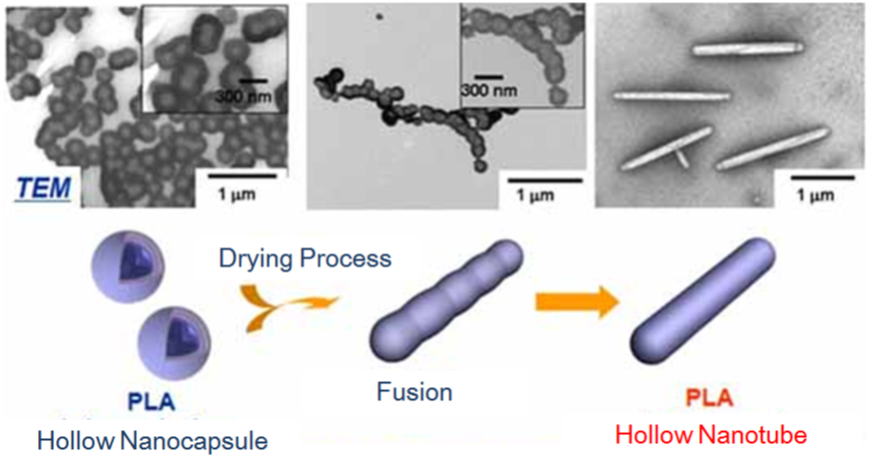

Using silica nanoparticles as substrates for the alternative layer-by-layer assembly method, the silica nanoparticles covered with layer-by-layer stereocomplex films of PLLA and PDLA can be fabricated. The removal of silica cores from these particles with hydrofluoric acid gives the PLA hollow nanocapsules. The hollow nanotubes are successfully fabricated through the one-dimensional fusion of the hollow nanocapsules.

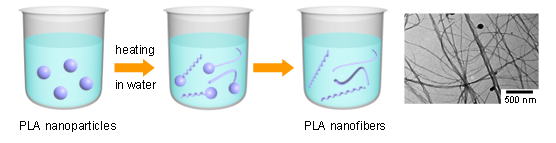

We also found that PLA nanoparticles dispersed in water were transformed into nanofibers by simply heating above the glass transition temperatures of the hydrated PLAs. Nano particles of PLA possessing reactive functional groups are also prepared. In our laboratory, the nanostructure of polylactides and their morphology are invesgigated for material application.

References

(3) Kenta Kondo, Toshiyuki Kida, Yuji Ogawa, Yuuya Arikawa, Mitsuru Akashi, “Nanotube Formation through

the Continuous One-dimensional Fusion of Hollow Nanocapsules Composed of Layer-by-layer Poly(lactic

acid)s Stereocomplex Films”, J. Am. Chem. Soc., 132, 8236-8237 (2010).

(4) Toshiyuki Kida, Kenta Kondo, Mitsuru Akashi, “Fabrication of Nanofibers through a Unique Morphological

Transformation of Poly(lactic acid) Particles in Water”, Chem. Commun., 48, 2319-2321(2012).

(5) Tran Hang Thi, Michiya Matsusaki, Mitsuru Akashi, “Photoreactive Polylactide Nanoparticles by the Terminal

Conjugation of Bio-based Caffeic Acid”, Langmuir, 25, 10567-10574 (2009).

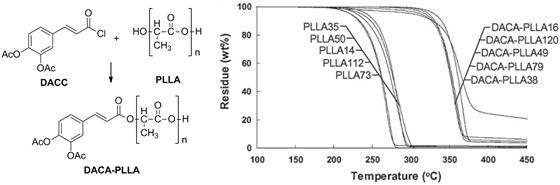

3. Thermal Property Control

It is important to improve thermal resistant properties of polymers. PLA starts to be hydrolyzed around 250 degree. We modified the chain end hydroxyl group with diacetylcinnamoyl chloride (DACC) to obtain polymers that do not hydrolysised over 300 degree.

References

(6) Tran Hang Thi, Michiya Matsusaki, Hiroshi Hirano, Hiroaki Kawano, Yasuyuki Agari, Mitsuru Akashi, “

Mechanism of High Thermal Stability of Commercial Polyesters and Polyethers Conjugated with Bio-Based

Caffeic Acid” J. Polym. Sci. Polym. Chem., 49, 3152-3162 (2011).

(7) Tran Hang Thi, Michiya Matsusaki, Mitsuru Akashi, “Thermally Stable and Photoreactive Polylactides by the

Terminal Conjugation of Bio-based Caffeic Acid”, Chem. Commun., 3918-3920 (2008).

back to PROJECT